This video is taken when our windmax wind generator is on the 5.9 feet test pole and the wind is 10 mph according to weather channel. the blades performs extremely well and spinning very fast at low noise. imagine the much greater performance if this wind generator is at 26 feet high !! The blade diameter is 1.4 meter or 4.9 feet. While at the same wind speed, the old style wind turbine with mechanical furling with 8.2 feet diameter or longer blades doesn't perform, the blades barely moved. Instead, the wind generator head is turning around, which is very bad. the blades for these old style wind turbines have poor design and such low efficiency, it can't capture the power in the wind even with the larger swept area, that is the myth about these blades with larger swept area, most people would think that the blades with larger swept area always performs better than blades with smaller swept area, that is totally untrue, if the blades with larger swept area won't operate/spin efficiently, it can't capture the power in the wind, and it won't output energy !!

The energy output is the energy converted by the turbine blades into mechanical energy, the turbine blades need to spin in order to convert all the wind's power to mechanical power. The low efficiency turbine blades don't spin or barely move, there is no energy output !!!

Rated energy output of the old style wind turbines with mechanical furling and low efficiency blades is very deceiving because the blades have such low efficiency that the larger swept area output little energy, some of the old style wind turbines with mechanical furling and low efficiency claim 1000w, 2000w or more, the actual output is much lower.

Patented, ISO and CE certified WindMax H series is the next generation system built with advanced technology, it is light weight and easy to install. It performs much better and much more reliable than older style wind turbines using furling which is the outdated technology.

The most reliable, most efficient wind turbine with lowest noise level and Incredible 134 mph (60 m/s) survival speed

Our wind turbine is made in modern ISO 9001 certified production facilities. Our Factory is ISO 9001 certified for implementation of quality management system for "DESIGN, DEVELOPMENT AND MANUFACTURING OF SMALL WIND TURBINES". ISO certificate ensures wind turbines to have superior quality and consistent performance.

Low noise level, neighborhood friendly: Pole adjacent noise level is < 55dBA, conforming to IEC 61400-11 wind turbine standard for Noise Measurement. Perfect choice for residential and rural, industrial, RV and marine applications.

CE and ISO certified

H Series Wind Turbine History

- The H series wind turbine was made available commercially on the worldwide market in 2004.

- Wind turbine patent was awarded in March of 2004.

- CE certification was awarded in July of 2005.

- ISO certification was awarded in March of 2006.

- More than 10,000 units have been sold worldwide.

- Documents available upon request.

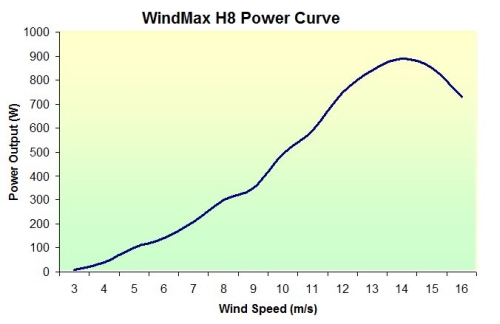

Maximum power : 900w

Rated Power: 750w

5 Years Limited Warranty

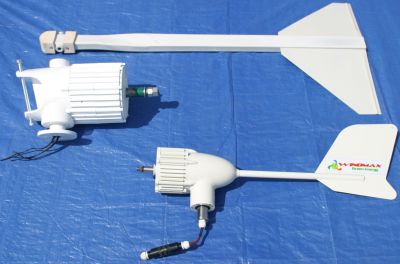

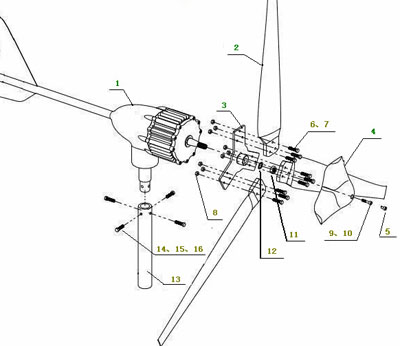

WINDMAX-H8 system includes generator with slip ring, hub, 3 blades, nose cone, tail, wire connector, Bolt-on Pole Collar, wind/solar hybrid controller and screws/bolts/washers/nuts needed to assemble the wind generator

Higher Efficiency = Higher Output and More Energy

Hidden cost of old style wind turbines with traditional mechanical furling

Low Efficiency Blades: Even with larger swept area, due to the low production quality and poor aerodynamic design, these old style blades can't capture the power in the wind efficiently. see below table for details.

Poor performance: The furling mechanism is not responsive to the constant changes of wind speed and wind direction. The furling system kicks in either too early or too late to go back to normal operation. This results in poor performance.

High Maintenance cost: The furling components are easy to wear out and break. They need lots of maintenance...therefore they are not a good long term investment.

Heavy Weight: wind turbines with traditional mechanical furling are heavy...therefore they have higher shipping cost, hard to install and maintain.

High Noise Level: Old style wind turbines with traditional mechanical furling is developed without noise control in mind, NOT neighborhood friendly.

Low survival wind speed: 78 mph (35 m/s) survival wind speed can't withstand high winds without damage and turbine needs to be taken down when wind speed exceeds 78 mph, output will diminish during high wind speed events.

900W maximum/750w rated 24V WINDMAX Wind Turbine system with Slip Ring, High Efficiency, Electromagnetic speed limitation, blade over-speed braking and hybrid solar/wind power output capability with 25 year maintenance free life span.

WINDMAX Wind Turbine system WINDMAX-H8 is built for residential/industrial land, RV, water pumps, and marine applications

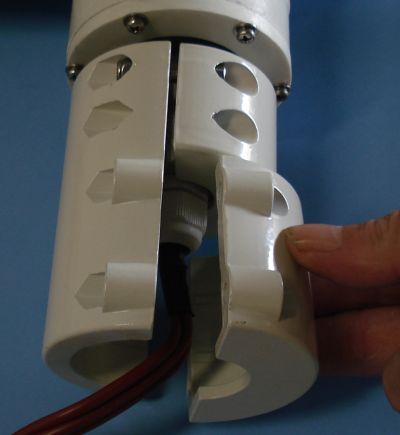

Wire connector included for easy connection, safety and durability.

User friendly pole connector included for easy installation, no welding needed to connect wind generator to pole

Patented, twisted high efficiency blades and extremely efficient aerodynamics design optimize angle of attack all along blades at different wind speeds and create the highest lift to drag ratio, blades are made using the latest advanced thermoplastic engineering and precision injection molding technology.

Multifunctional Hybrid controller combines the functions of solar/wind charge control, dump load, over-charge protection, short-circuit protection and pole-confusion protection

Strong Neodymium magnet PMA, the unique winding and multi-pole design reduces the start-up torque of the alternator that assures the it can generate more electricity at low wind speed than other systems.

Compared to Old style turbines below - hard-to-install pole mount, unprotected connection wires, basic function controller, problematic furling components, and hand made low efficiency fiber glass blades

| Comparison of Hybrid Wind Generators with Aerodynamic Braking, Electromagnetic Braking, Slip Ring vs. Old Style Wind Generators with Mechanical Furling | ||

Hybrid Wind Generators with Aerodynamic Braking, Electromagnetic Braking, Slip Ring | Old Style Wind Generators with Mechanical Furling | |

| Overall | High performance, high efficiency, high reliability and superior workmanship, designed to work from low to high wind speeds. Patented, twisted high efficiency blade and extremely efficient aerodynamics design optimize angle of attack all along blades at different wind speeds and create the highest lift to drag ratio Slip Ring Design | Average efficiency, average reliability and average workmanship with deceiving rated output, designed for perfect wind conditions at rated wind speed, much lower output at realistic wind conditions, lower output at low wind speed, stop working at high wind speed. Even with larger swept area, blades with low efficiency and poor aerodynamic design can't capture the power in the wind efficiently. No Slip ring implemented |

| Slip Ring Design | Advanced "Slip Ring" design, connection cable won't get twisted with WindMax's slip ring design. | Don't have slip ring design, the connection cable will get twisted as the wind shifts direction and requiring constant untangling. Tangled wires can be damaged and connections can be lost with potentially disastrous consequences. |

| Wind/Solar Input | Can be used as either wind turbine only or wind/solar hybrid system. Integrated wind and solar power sources to capture the most energy in all conditions. Since solar and wind energy availability differs by locations, seasons and climates, solar and wind energy can be mutually complementary in that solar and wind hybrid systems make full use of wind and solar energy together to generate as much power as possible. | Work with wind only, NO electricity generation when wind speed is too low |

| Design, Quality, Reliability & durability | Highly reliable, Innovative two moving part design with 25-year maintenance-free generator life span. Excellent workmanship, stainless steel parts, high strength aluminum die cast generator housing. It is designed for various working conditions such as severe climate, sand and salt corrosive environments and marine usage. The generator features class B insulation, IP55 class protection, and is designed with a sufficient cushion of overload to ensure overall wind turbine reliability. Slip ring design and electric braking ensure higher reliability than old style wind turbine with mechanical furling Durable rotor blades are made of mixed nylon and reinforced fiber glass materials using the latest advanced thermoplastic engineering and precision injection molding technology for high strength, flexibility and aerodynamic braking. | Much less reliable three moving part design, furling components wear out quickly and require a lot of maintenance. This would lead to possible mechanical abrasion, cause vibration, malfunction, and failure of the wind turbine and other possible negative results in the long run. Poor reliability as result of no slip ring design, the connection cable from wind generator to controller can be easily twisted and tangled , Tangled wires can be damaged and connections can be lost with potentially disastrous consequences. Old style system with average workmanship, average quality parts may rust in a few years, not designed for rough working conditions such as severe climate, salt corrosive environments and marine usage. Due to the fact that most installations are in very remote and inaccessible locations, the old style systems make regular maintenance costly and sometimes impractical. Hand made blades using fiber glass material with unavoidably inconsistent performance and quality. Built for amateurs/hobbyists, not for realistic electricity generation |

| Braking & Efficiency | High efficiency: Abandoned the traditional failure-prone mechanical furling system and solved efficiency, safety and reliability problems facing most small wind turbines. Advanced speed limitation is achieved through electromagnetic speed limitation supplemented by aerodynamic speed limitation by blade deformation. Combination of Electromagnetic braking and aerodynamic braking maximizes energy capture by extending turbine’s operating speed range into higher speed winds and lower speed winds which are missed by the old style wind turbines. | Average efficiency: Braking depends on unreliable, problematic mechanical furling which only works well in an ideal, wind tunnel test environment. Realistically, wind speed and wind direction changes frequently and mechanical furling doesn’t have instantaneous response to actual changes of wind status. The furling system kicks in either too early or too late to go back to normal operation. This results in average efficiency. |

| Performance at low wind speed | Strong Neodymium magnet PMA, the unique winding and multi pole design reduces the start-up torque of the alternator that assures the it can generate more electricity at low wind speed than other systems. | Generator is not designed to work efficiently at low wind speed |

| Performance at high wind speed | Incredible 134 mph (60 m/s) survival speed, system operates and generate electricity up to 134 mph | Lower survival wind speed at 78 mph (35 m/s), start to furl and reduce output at 20 mph (9 m/s), wind turbine needs to be taken down when wind speed exceeds 78 mph. |

| Blade Design & efficiency | Extremely efficient rotor aerodynamics: With patented and optimal twisted blade design, angle of attack is optimized all along blade at different wind speeds and therefore creates the highest lift to drag ratio. Twisted, high efficiency blades are insensitive to wind direction so they work much efficiently in real wind conditions. The twisted blades has very good self-start ability, even at low air velocity and has the capability of smooth running, high torque and high RPM, which makes it suitable for electricity generation. In summary, H series highly efficient blades means smaller size blades for same or more power. Advanced aerodynamics design to capture maximum wind energy. The blades have exceptional consistency and aerodynamic outline with a mass distribution that ensures the rotors operate with minimal vibration. In high wind speed conditions, patented blades will generate a reverse reluctance torque, so that the blade efficiency falls and the blade rotation speed starts to decline. With the continuing reluctance torque, blade rotation speed is limited to a certain range to prevent damage to the wind turbine blades. | Low efficiency with poor aerodynamics design. Even with larger swept area, due to the low production quality and poor aerodynamic design, these old style low efficiency blades can’t capture the power in the wind efficiently. Blades have higher noise level, blades have no aerodynamic braking feature, blades won't operate at high wind speed. |

| Blade Material & Quality | Made of mixed nylon and reinforced fiber glass materials using the latest advanced thermoplastic engineering and precision injection molding technology for high strength, flexibility and aerodynamic braking. | Hand made blades using fiber glass material with unavoidably inconsistent performance and quality. Built for amateurs/hobbyists, not for realistic electricity generation |

| Maintenance | 25-year maintenance-free generator life span, maintenance free design has a minimum of moving parts with inherent reliability. | The furling components such as bearings are easy to wear out. lots of maintenance required |

| Weight | Light Weight, 40 to 50 lbs | Heavy Weight, 150 lbs or more |

| Installation | Light weight, compact and modular generator design makes installation simple. Straightforward step by step instructions. | Heavy weight and old style design of generator and furling components result in complex and lengthy installation. |

| Wire connection | wire Connector from wind generator to controller included for safe and easy installation | No connector included |

Side-by-side comparison of Hybrid Wind Generators with Aerodynamic Braking and Electromagnetic Braking

vs. Old Style Wind Generators with Mechanical Furling

Pictures of Installed WindMax H Series Wind Turbines from Customers

Click HERE to View/Download WindMax H Series USER MANUAL

Click HERE to View/Download WindMax H Series USER MANUAL Click HERE to View/Download Hybrid Charge Controller USER MANUAL

Click HERE to View/Download Hybrid Charge Controller USER MANUALWINDMAX-H8 system includes generator, hub, 3 blades and tail and wind/solar hybrid controller

Higher Power Output Small Wind turbine system under low wind condition

Great for cabin, backup power, battery charging, RV and remote power

Perfect Wind turbine system to complement the existing solar systems

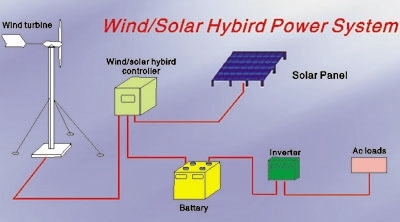

Wind/solar hybrid controller can support combined wind generator load up to 900w and solar load up to 320w

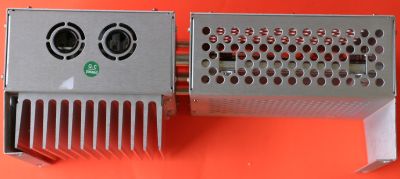

We have two versions of controllers. The controller we ship to you may be different from what is shown in above picture. If you want to specify the controller, please contact us when you order.

Can be used as either wind turbine only or wind/solar hybrid system.

Can be used as either wind turbine only or wind/solar hybrid system.

Recommended Solar Panels: up to 320w (available in our store)

Optional Inverter: Exeltech, Outback or Xantrex Inverters

Click HERE to buy inverter

The Windmax H series Wind turbine system is the perfect choice in a smart investment for a renewable energy solution built on advanced technologies. The Windmax H series defines a new level of superior performance and reliability by using:

1. Strong Neodymium magnet PMA, the unique winding and multi pole design reduces the start-up torque of the alternator that assures the WINDMAX-H series can generate electricity at low wind speed.

2. Advanced aerodynamic braking by patented nylon/reinforced fiber glass blades.

3. Electromagnetic over-speed control, no more problematic mechanical furling.

4. Integrated solar-wind hybrid power generation.

5. Innovative low maintenance two-moving-part system design.

6. Easy to Install, Light Weight and highly reliable.

7. Generator: The generator is built using high-performance rare earth neodymium permanent magnets, so the alternator is compact and light weight with a high power generating efficiency. Generator housing is made using precision cast technology from high strength aluminum to assure a high quality finish. It is designed for various working conditions such as severe climate, sand and salt corrosive environments and marine usage.

8. Rotor Blades: Advanced airfoil design to capture maximum wind energy. Made of mixed nylon and reinforced fiber glass materials using the latest advanced thermoplastic engineering and precision injection molding technology for high strength, flexibility and aerodynamic braking. The blades have exceptional consistency and aerodynamic outline with a mass distribution that ensures the rotors operate with minimal vibration.

In summary, Windmax H series are the most well built, reliable, most efficient and cost-effective small wind turbines available on the market today.

The result: greater energy production yield and lowest ownership cost.

Design Features

Advanced over-speed control mechanism vs. old style furling

Problems with old style furling:

Old style furling works well in an ideal, wind tunnel test environment. Realistically, wind speed and wind direction changes frequently and mechanical furling doesn’t have instantaneous response to actual changes of wind status. Especially in bad weather conditions, small wind turbine furling components wear out quickly, therefore, increases maintenance costs and shorten wind turbine service life or causes system failure.

Most of old style furling based wind turbines have three moving parts. It is the moving parts for mechanical over-speed protection that wear out and require a lot of maintenance. Operation of furling based wind turbines would lead to mechanical abrasion, cause vibration, malfunction, and failure of the wind turbine and other devastating results in the long run.

The rule of thumb for a reliable wind turbine is that the fewer the moving parts, the more reliable the wind turbine is.

Windmax Solution:

Windmax H series adopted Innovative over-speed control so it improves the reliability by abandoning the moving parts for mechanical over-speed protection and minimizing the moving parts to only two.

Innovative over-speed control design of the Windmax H series:

Windmax H series speed limitation abandoned the traditional failure-prone mechanical furling system and solved safety and reliability problems facing most small wind turbines. Advanced speed limitation of Windmax H series is achieved through advanced electromagnetic speed limitation supplemented by aerodynamic speed limitation by blade deformation. Electromagnetic braking is used in combination with Aerodynamic braking to reduce the rotational speed of the generator.

Combination of Electromagnetic braking and aerodynamic braking maximizes energy capture by extending Windmax H series turbine’s operating speed range into higher speed winds and lower speed winds which are missed by the old style wind turbines.

1. Electromagnetic speed limitation:

Controller will monitor the wind generator rotation through the wind generator output voltage and frequency, and will timely control wind generator rotation by generating reverse reluctance torque if necessary, according to different wind conditions and battery status. Electromagnetic control features quick response, high reliability and therefore ensures the entire control system to be highly reliable.

2. Blade aerodynamic braking:

In high wind speed conditions, patented blades will generate a reverse reluctance torque, so that the blade efficiency falls and the blade rotation speed starts to decline. With the continuing reluctance torque, blade rotation speed is limited to a certain range to prevent damage to the wind turbine blades.

Higher performance at low wind speed

Problem with small wind turbine system on the market today

The most challenging problem facing small wind turbine systems is that power output is very low or close to nothing under low wind condition. The wind speed in most locations don’t stay at rated wind speed all the time, wind turbine actually operates at wind speed lower than rated wind speed at most of the time. In order to have good overall energy output, it is critical for small wind turbine to output as much as power at low wind speed.

WindMax Solution:

Strong Neodymium magnet PMA, unique winding and multi pole design reduces the start-up torque of the alternator that assures the WINDMAX-H series can generate electricity at low wind speed. WindMax system components such as wind generator and blades are designed to output more electricity at low wind speed than other small wind turbines on the market today. WindMax system’s excellent power output under low wind speed results in greater energy production yield and lowest ownership cost.

Wind-solar hybrid power generation wind turbine system

Problem with single source renewable energy system:

1st Generation single source renewable energy systems such as solar systems or wind turbines don’t use renewable energy efficiently. Wind turbines creates less output during the summer, whereas during the winter the solar panels will produce less output.

Windmax Solution:

Our Windmax hybrid solar-wind turbine integrated wind and solar power sources capture the most energy in all conditions. Since solar and wind energy availability differs by locations, seasons and climates, solar and wind energy can be mutually complementary in that solar and wind hybrid systems make full use of wind and solar energy together to generate as much power as possible compared to a single energy source for power generation. A solar & wind hybrid system is more cost-efficient than wind or solar alone.

Easy-to-install, light weight, compact, reliable and maintenance-free wind turbines, designed for both land-based and marine applications.

Problem with old style wind turbine systems:

Most old style wind turbines are heavy weight with unpredictable reliability, hard to install and require lots of maintenance. Due to the fact that most installations are in very remote and inaccessible locations, the old style systems make regular maintenance costly and sometimes impractical.

Windmax Solution:

Windmax H series maintenance free design has a minimum of moving parts with inherent reliability. Our light weight, compact die-casting aluminum alloy generator design makes installation very easy. Rotor blades built with latest advanced thermoplastic engineering and precision injection molding technology is durable and efficient.

WindMax H series components built with advanced technologies

Generator:

Generator: The generator is built using high-performance rare earth neodymium permanent magnets, so the alternator is compact and light weight with a high power generating efficiency. The unique winding and multi pole design reduces the start-up torque of the alternator that assures the WINDMAX-H series can generate electricity at low wind speed. The generator features class B insulation, IP55 class protection, and is designed with a sufficient cushion of overload to ensure overall wind turbine reliability.

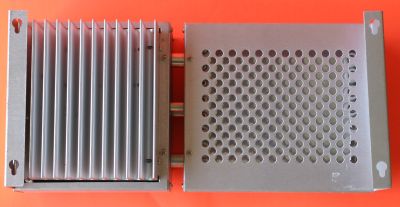

Generator housing is made with precision cast technology from high strength aluminum to assure a high quality finish. It is designed for various working conditions such as severe climate, sand and salt corrosive environments and marine usage. Aluminum die cast alloys can withstand the highest operating temperatures of all die cast alloys. Ideal for demanding environments, it offers high strength and rigidity along with good corrosion resistance and heat dissipation.

Rotor blades:

Patented Blade design vs. traditional hand made fiber glass blades:

Our Blades are made with the latest thermoplastic engineering and injection mold technologies. The blades are made of mixed reinforced fiber glass and nylon materials. These manufacturing technologies ensure the highest strength, flexibility of blades and consistency of the blade shapes. The blades will automatically slow the turbine in strong winds and reduce noise.

A set of 3 Blades designed to capture as much wind energy as possible. Patented airfoil blade design makes the system run much more efficiently and the rotor blades are made with the latest advanced thermoplastic engineering and precision injection molding technology.

The blades have exceptional consistency and aerodynamic outline with a mass distribution that ensures the rotors operate with nearly no noise and minimal vibration.

The blades feature lower start-up and cut-in speed and begin producing power at 2 m/s or 4.5 mph.

Solar/Wind Hybrid Charge Controller:

This multifunctional Hybrid controller combines the functions of AC to DC rectifier, load control and dump load control for wind and/or solar systems. It eliminates the need for separate rectifier, solar charge controller and wind turbine controller. It is the most cost effective solution for renewable energy systems.

Main Features

# High Reliability: Extra large heat sink and efficient ventilation design ensure reliable and efficient operation.

# Great for hybrid wind/solar system, hybrid controller can support battery charging from simultaneous wind generator load and solar load combined up to 550w.

# Charge Control: Constant voltage series PWM regulation to provide highly efficient battery charging increase battery capacity and life.

# Load control and diversion control: The controller has over-charge protection, protection, short-circuit protection, pole-confusion protection and automatic dump-load function. It is reliable with a highly efficient, long service life.

# Built in "ON/OFF Switch" to connect the wind turbine or solar panels to the controller.

# Uses advanced technology and automated production to provide exciting new features at a competitive cost.

Technical Specifications:

Model | WINDMAX-H8 |

Wheel diameter | 5.9 Feet (1.8M) |

Blade material | glass-fiber, strengthened nylon |

Number of Blades | 3 |

Speed-limitation mechanism | Electromagnetic speed limitation and blade over-speed braking |

Start-up speed | 2.3 m/s or 5.1 mph |

Cut-in speed | 3 m/s or 6.7 mph |

Survival speed | 60 m/s or 134 mph |

Rated speed | 26 mph |

Rated power(W) | 775W @ 12.5 m/s or 28 mph, 750W |

| Max power (W) | 900W |

Rated voltage(v) | DC24V |

Alternator | 3 phases PMA |

Tower height(m) | Fits 2.125" steel pipe, 1.5" or 2" steel pipe can be used with modifications 8 |

| Solar Input | 1 of 24V 320W or 2 of 12V solar panels |

Weight of system(LB) | 41 |

We have two versions of Pole mounting brackets: bolt-on collar mount and weld-on ring mount. The bracket we ship to you may be different from what is shown in above picture. If you want to specify the pole mount bracket, please contact us when you order.

Click HERE to View/Download PDF USER MANUAL (2.81M PDF)

Click HERE to View/Download PDF USER MANUAL (2.81M PDF)Click HERE to View/Download Wind Turbine Warranty Information